CONTENTS:

Star

Trek TOS Props |

Communicators

Phasers

Tricorders

Star

Wars EP IV-VI Props |

Helmets

Blasters

Stormtrooper Armor

Lightsabers

Astro-Mech Droids

How-to Guides

Misc.

Sci-Fi Props |

Cylon

Centurion

Viper Pilot Helmet

M41-a Pulse Rifle

Motion Tracker

B5 PPG

1964-1976

GIjOE Figures |

Retro

Box Designs

Repair/Restoration

Replica Parts

40th Anniversary

World

War II Militaria |

Replica

Weapons/Gear

Reenactment Units

ME262 Project

Civilian

Marksmanship Program |

M1

Garand Rifle

M1903 Springfield

Rifle

M1 Carbine

Other

Stuff |

Discussion

Board

Lauren Photo Albums

Egner II

Design

Please

note, that the images, logos, and respected artworks, are property of

the original copyright owners. TK560 has no affiliation with any of the

intellectural property owners. This is a fan site dealing with movie and

television replica props, original GIjOE action figures, World War II

memorbilla, and marksmanship/ firearms interests. Most of the images used

on this site are photgraphed by the site owners. Official logos are used

to identify specific products/ manufacturers.

Build your own Star Trek The Original Series Phaser I & II

The following tutorial is the work of Will from PA, and you might have seen his work in the ASAP boards. A few months ago, he asked that I host some of his images on this site. After adding a host of images, templates, and works in progress, Will and I are presenting this tutorial on how to make your own Star Trek Phaser from scratch. Follow along with the construction, down load the templates and get in the shop and build you one. Will has been making communicators and phasers for years, and now he wants to share his experiences with the prop building community. Click here to learn how to make your own Star Trek Communicator. Also learn how to make your own TOS Tricorder too!

Supplies |

Tools |

| wood(any

2x4 will do) |

Band

Saw |

The Reference Prop

| Here is the reference phaser. This is one of the prop replicas that you use to be able to find at the SciFi conventions. The maker is unknown but possibly made by Starland. Will uses a carpenters contour guide to make the templates from. |

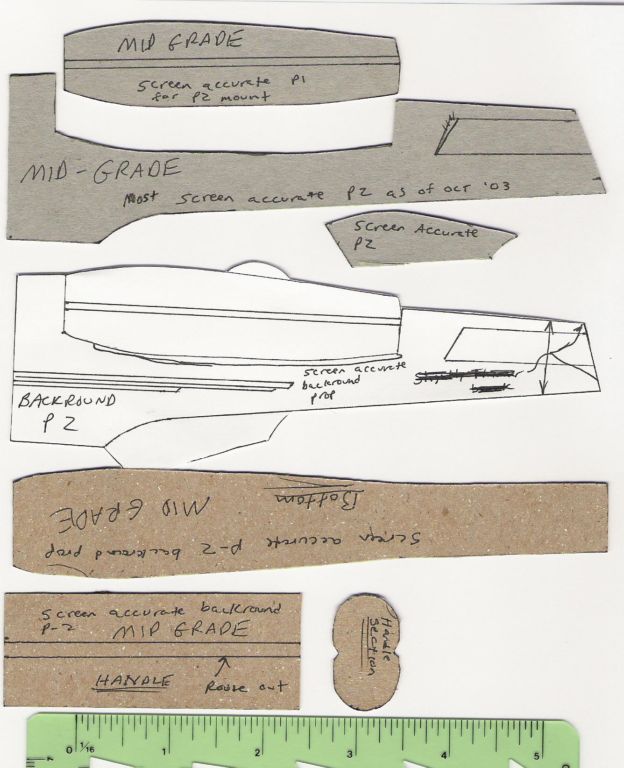

Templates

|

Download the Phaser I template file. Download the Phaser II template file. Print it out on your printer. The scale is there to provide a reference for scale. |

Body Construction

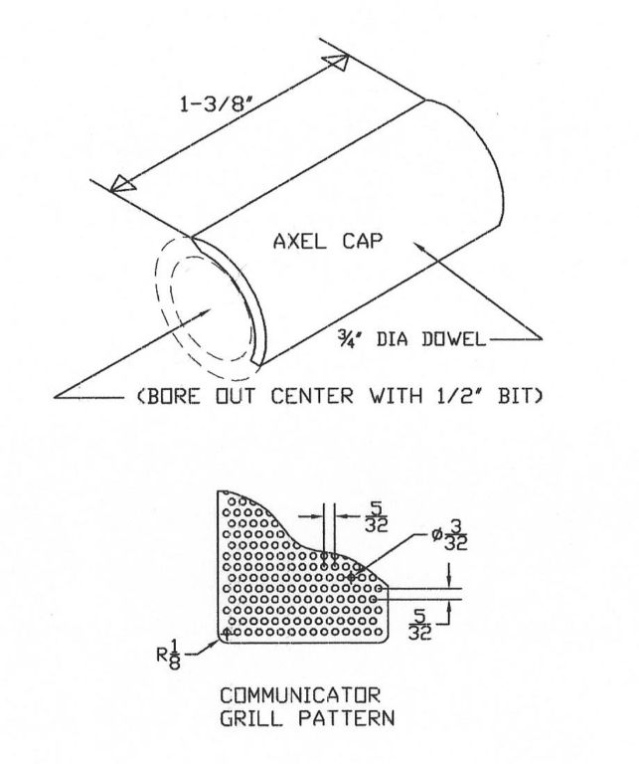

Grill Construction

[more

images pending] [template pending]

Draft a grid on a piece of paper (3/32 hole on a 5/32 spacing staggered

alignemnt)

Lay the grid on sheet metal

Punch each intersection of the grid using awl

Drill each punch mark with 3/32" bit (approx 200 holes to drill)

Fold the flat piece of sheet metal to form the shape of the grill

Bend the coat hanger to fit around the grill and bend at approx 45 degrees

at the ends.

Cut 2 sections from a 1/2" metal rod for the wheels.Drill axle holes(

I just use an 8 penny nail for the axle)

Drill into the wheels using a bit the size of the coat hanger (usually

1/16")

Stick the free ends of the coat hanger frame into the wheels

Crazy glue the grill onto the frame (crazy glue allows you to "spot

weld" metal together.

Another option is to purchase some of the correct grid material. One source would be the cheap grill materials for speakers found at the local Raido Shack.

A final option would be to purchase the correct material from a wholesaler. This can be expensive. One quite for a 4' x 8' sheet of grill materials was into the hundreds of dollars. Ouch.

Morie' Disk

Information pending, but for now, a good source is old computer hard drives! The old Conner series "Tall" type drives have aluminum bushing on the inside that are nearly perfect. Stack three together and volia! Instant morie` disk. [images pending]

Control Panel

Information pending, but for now consider a 1/16 thick aluminum stock. Cutting the "speaker" square hole is the hardest part. [images pending] [template pending]

Jewels & Bezels

Information pending. but most hobby stores have lots of jewels or rhinestones. [images pending]

Finished Prop

*note: all images

regarding the construction of the communicator body are property of Will,

PA. Used with permission.